The Sheroz Earthworks Statements

Table of Contents9 Simple Techniques For Sheroz EarthworksMore About Sheroz EarthworksSheroz Earthworks Fundamentals ExplainedSome Known Facts About Sheroz Earthworks.The Of Sheroz Earthworks

Obtaining the ground to simply the ideal level is no easy task. 3D maker control systems enable automated blade control, directing the dozer blade to specifically the ideal angle at exactly the best areas. This system boosts accuracy and performance by a huge margin. Additionally, by making certain degree ground, it makes best use of security for employees once the structure procedure starts.Scratching features rather like sleeping, yet on a much finer and more exact scale.

Maker control can add value to various agriculture tasks, including: You can use the modern technology to without effort monitor and map area info in real time, making browsing and assisting your tools less complicated than ever. Secret attributes include aided guiding that gets rid of much of the concern from the driver, water management, return tracking and camera input.

Machine control is sturdy enough for hefty area usage and offers the flexibility to execute numerous drain system applications. Accomplishing maximum upright precision is critical when grading and developing land for farming. Equipment control systems can manage this tough application promptly and successfully, enabling you to raise productivity and decrease downtime in the area.

The Best Strategy To Use For Sheroz Earthworks

Experience quantifiable renovations in vital locations like maker and asset organizing, fuel usage and preventive maintenance. Reinforce task site security and various other crucial processes by boosting precision and dependability in essential mining procedures. Remove imprecise hands-on field measurements and raise reporting flexibility in your geotechnical and ecological monitoring programs with these innovative data-capturing remedies.

Whatever the focus of your most current building and construction job is, you can gain from equipment control. It can improve your progressing and sharpen your digging, and it can do all of it while offering you comments on where each rover gets on the site at any kind of provided moment. As a movie director, you can use the system software to see the entire site at the same time and observe every place that is being modified in real time.

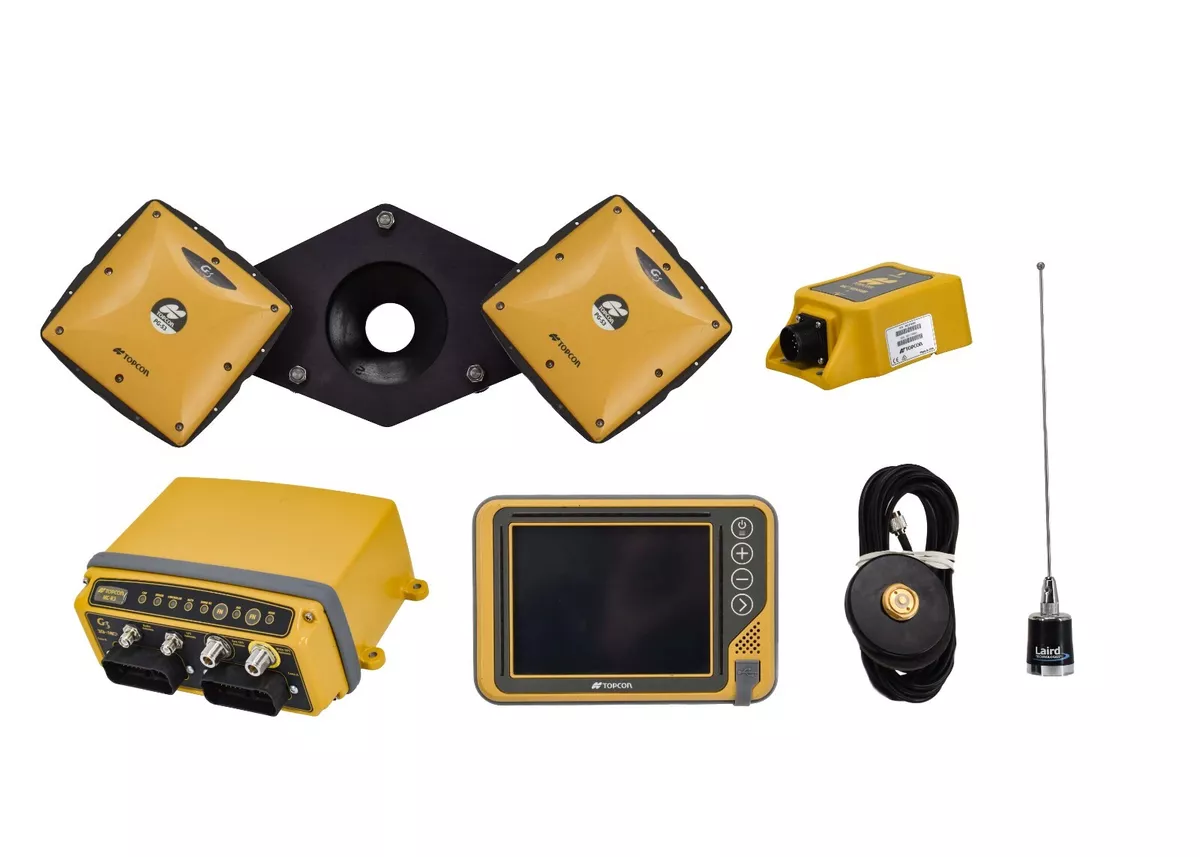

SITECH Southwest can get you the equipment control system you require to reinvent your construction procedure (https://perpetual-streetcar-7f1.notion.site/Unlocking-Precision-with-Topcon-GPS-0c2825638577400995d3f1e51f7ea5a6?pvs=4). As an accredited Trimble dealership, we supply top-notch equipment for all the building and construction processes listed above. Just connect with us today to obtain your equipment control system!.

Get This Report on Sheroz Earthworks

For this to work, turning lasers were established to transfer signals that could be grabbed by sensing units placed on dozers or graders. This provided operators the fundamental details they needed for their equipments. Yet, in comparison to modern equipment control, these very early systems were still very limited at providing a complete and precise photo and were also typically too expensive or complicated.

It is clear that there is an absence of fresh talent entering the market. Specifically, professionals have problem drawing in youths and, as a result, there are less drivers going into the career. Needs to this fad continue, the industry will be left with a lack of seasoned and reliable operators, which means that the quality and performance of projects will be impacted by a significant abilities void.

Exceeding merely providing drivers with an aesthetic overview to container or blade setting, automated maker control moves the blade to grade by speaking to the maker's hydraulics - fj dynamics auto steer price. Unlike with routine machine control, automated device control technology positions the responsibility for accuracy and speed firmly in the hands of performance-enhancing technology

When considering the existing building and construction landscape, it is clear that, despite its substantial benefits, maker control automation is not being adopted throughout all makers at an equal rate. In truth, although automation is being embraced on devices like and dozers, the uptake has actually been much slower for excavators, with the fostering rate of automated device control on these machines still approximated at around 10% in Europe in comparison to a rate of over 50% for dozers.

Things about Sheroz Earthworks

Today, an increase in performance on excavators can be noted as boosted accuracy and minimized over-digging being fairly very easy to prove. Nevertheless, it is clear that the sector now needs to reassess the demands for excavators. With the needs for efficiency enhancing and a scarcity of competent drivers, building needs to accept the advantages that buying automated machine control can bring.

If you are wanting to boost your efficiency with today's innovation we are below to help. Your existing personnel can be trained to perform all aspects of the laid out and get tasks of the day to day site needs in a no nonsense technique.

As expected, the excavator drivers are under an incredible pressure to deliver an optimal efficiency while trying to achieve their efficiency objectives at the exact same time. That is why all sort of help and improvements are a lot more than welcome pertaining to boosted precision and optimum manufacturing. As constantly, innovation is the key.

The Ultimate Guide To Sheroz Earthworks